Design

Airbus summit comes with raft of environmental design initiatives

Andrew Salerno-Garthwaite rounds up the latest environmental-centric design updates from this year's Airbus Summit.

Image: copyright

The annual summit of European aerospace prime Airbus saw a fleet of new partnerships and initiatives introduced that are geared to pushing the aviation industry toward reaching environmental goals in sustainability.

The projects announced between 31 November and 1 December cover a range of improvements, with interventions at a number of stages in the hydrogen fuel delivery ladder, as well as partnerships with CERN and Renault to improve electrification prospects, and progress in sustainable aviation fuel (SAF).

Airbus to fly a new aerodynamic demonstrator by the end of the year

Airbus used its annual summit to introduce the DisruptiveLab, a new flying laboratory meant to test ideas aimed at improving aircraft performance and lowering CO2 emissions from helicopters.

The DisruptiveLab will test a new aerodynamic architecture designed to cut fuel consumption, as well as pursue hybridisation with a fully parallel hybrid propulsion system that allows the battery to be recharged in-flight. The demonstrator will begin flight testing before the end of the year.

“The DisruptiveLab goes another step further in Airbus Helicopters’ ambitious strategy to reduce the environmental impact of its helicopters and to lead the way towards a sustainable aerospace industry,” said Bruno Even, CEO of Airbus Helicopters.

To validate the combined impact on CO2 reduction, which may be up to 50%, the architecture and parallel hybrid propulsion system could only be evaluated on a brand-new demonstrator, explained Even.

An aerodynamic fuselage made of aluminium and composite material is part of the DisruptiveLab’s architecture. This was created with the goal of lowering drag and, consequently, fuel consumption.

Because of the way the blades are integrated into the rotor, the rotor head can be made smaller, reducing drag and raising energy efficiency while also reducing noise. A more efficient Fenestron tail rotor built into its lighter rear fuselage also adds to better performance.

The French Council for Civil Aviation Research Council has included the DisruptiveLab demonstrator in its roadmap, and the French Civil Aviation Authority has contributed funding to it as part of the French Stimulus plan, which is a component of the European Plan, Next Generation EU, and the France 2030 plan.

The strategy of Airbus Helicopters relies on demonstrations to quickly test and develop new technology. In 2020, the company began developing its first FlightLab demonstrator. The FlightLab is primarily focused on researching and developing technologies related to improved autonomy and safety technology bricks and operates on an existing H130 platform. The DisruptiveLab, on the other hand, will concentrate on enhancing aircraft performance and minimising environmental impact.

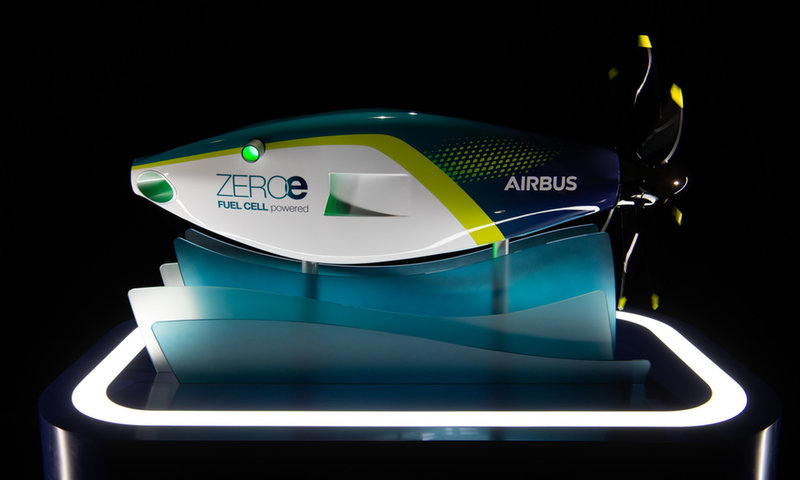

Hydrogen fuel cell being developed for launch by 2035

Airbus also announced that it is working on a new hydrogen-powered fuel cell engine. The propulsion system is being looked at as one of the potential alternatives to outfit an emission-free aircraft that will go into service by 2035.

By the middle of the decade, Airbus will begin testing this fuel cell engine architecture in the air and on the ground using its ZEROe demonstrator aircraft. Currently being converted to hold liquid hydrogen tanks and the distribution systems that go with them is the A380 MSN1, a flight test aircraft for new hydrogen technology.

Glenn Llewellyn, VP Zero-Emission Aircraft, Airbus, stated that fuel cells “are a potential solution to help us achieve our zero-emission ambition”.

"We are focused on developing and testing this technology to understand if it is feasible and viable for a 2035 entry- into- service of a zero- emission aircraft."

Fuel cell engines might be able to power a 100-passenger aeroplane with a range of about 1,000 nautical miles if the technology goals were met and scaled up, explained Llewellyn.

“By continuing to invest in this technology we are giving ourselves additional options that will inform our decisions on the architecture of our future ZEROe aircraft, the development of which we intend to launch in the 2027-2028 timeframe.”

Airbus' ZEROe Fuel Cell Engine

Because hydrogen can be produced from renewable energy sources without emitting any carbon dioxide, and because water is one of its main byproducts, it has been highlighted by Airbus as one of the most viable choices for powering a zero-emission aeroplane.

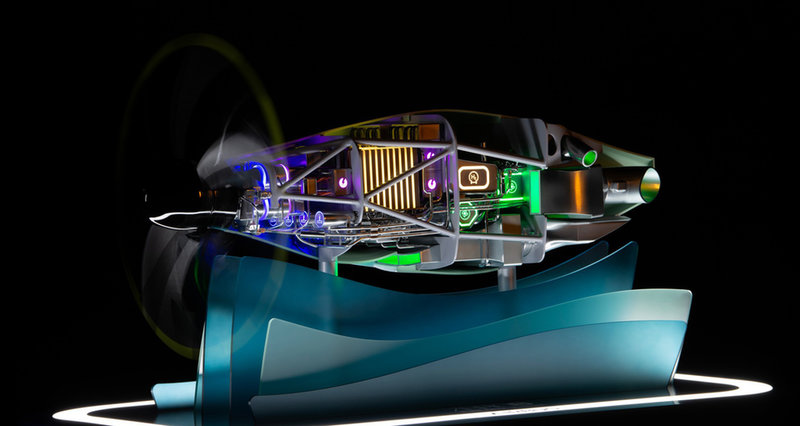

Hydrogen can be utilised as an aeroplane propulsion fuel in two different methods. The first method involves burning hydrogen in a gas turbine. The second method involves employing hydrogen fuel cells to turn it into electricity to power a propeller engine. In a hybrid-electric architecture, fuel cells can be connected with a hydrogen gas turbine in place of batteries.

Scalability is made possible by the increased power output of hydrogen fuel cells, particularly when they are stacked. Additionally, a hydrogen fuel cell-powered engine produces no NOx emissions or contrails, providing further advantages for decarbonisation.

For some time now, Airbus has been researching the potential of fuel cell propulsion systems in the aviation industry. As a joint venture with ElringKlinger, a business with more than 20 years of experience as a supplier of fuel cell systems and component, Airbus established Aerostack in October 2020. Airbus unveiled its pod-concept, which had six removable fuel cell propeller propulsion units, in December 2020.

Partnership with HyPort for hydrogen distribution

Airbus has partnered with France green hydrogen developer, HyPort, in a venture between ENGIE Solutions and the Regional Agency for Energy and Climate in Occitanie, to support the construction of one of the first low carbon hydrogen production and distribution facilities at an airport.

The production, storage, and distribution systems are currently undergoing final testing, and the construction of the hydrogen station at Toulouse-Blagnac airport was finished earlier this year. With a daily production capacity of 400kg of hydrogen, the station, which is expected to go into operation in early 2023 and will be able to power 50 ground transportation vehicles.

Working with HyPort, Airbus is developing a deployment strategy for the expansion of these hydrogen-powered ground operations, adjusting infrastructure capacity, production and distribution methods, and other factors to meet the anticipated rise in hydrogen demand over the next few years.

A roadmap describing needs and offering advice on operational safety, regulatory compliance, public acceptance, as well as the financial investment required for the broad use of hydrogen at airports, will also be provided under the partnership.

“Our involvement with HyPort demonstrates the tangible progress Airbus is making on its journey to secure the future energy ecosystems of tomorrow,” said Karine Guenan, VP ZEROe Ecosystem, Airbus.

“Using hydrogen to decarbonise all airport-associated ground transport in the 2020 to 2030 timeframe will pave the way for hydrogen availability for zero-emission aircraft by 2035.”

In order to assist airports in identifying the infrastructure needs for upcoming hydrogen aircraft as well as low-carbon airport operations across the whole value chain, Airbus introduced “Hydrogen Hub at Airports” in 2020. Following this, Airbus has partnered with numerous airport authorities, airlines, and energy suppliers in Europe, Asia-Pacific, and North America during the past two years.

Joint venture with ArianeGroup for the first ZEROe hydrogen refuelling facility

The first liquid hydrogen refuelling facility for ZEROe aircraft will be constructed at Toulouse, Blagnac airport by Airbus and ArianeGroup. The station is a joint venture, equally owned by Airbus and Safran, a leading firm in space propulsion technologies.

The liquid hydrogen fuelling system required for Airbus’ ZEROe demonstrator’s ground and flight test programme, which is scheduled to begin in the middle of this decade, will be designed, manufactured, and operated by ArianeGroup.

“Many of the technologies required for a zero-emission aircraft are already available in other industries, and liquid hydrogen handling is no exception,” said Sabine Klauke, chief technical officer, Airbus.

The ArianeGroup have pedigree in this role. For more than 40 years, liquid hydrogen has been the primary propulsion source for Ariane launch vehicles, built by ArianeGroup as the prime contractor.

The internals of the new Airbus ZEROe Fuel Cell Engine

Airbus and Neste partner on Sustainable Aviation Fuel

In order to enhance the production and use of SAF, Airbus and Neste, a global producer of renewable fuels, have signed a memorandum of understanding to cooperate in this area. Both parties agree that SAF is an important strategy for lowering aviation’s contribution to global warming, with the goal of this partnership being to quicken the transition to SAF in the aviation industry.

The ramp-up of SAF production is one of the main obstacles to boosting SAF use, according to Neste and Airbus. By working together, the companies hope to build the groundwork for advancing in SAF technology throughout the whole aircraft industry.

The partnership’s emphasis will be on fuel approval and testing of present and upcoming production technologies, as well as on the technical advancement of SAF and looking into how 100% SAF use may be made possible.

SAF is one of the most promising decarbonisation technologies in aerospace that can be used for today and tomorrow’s fleet of aircraft, according to Julie Kitcher, EVP communications and corporate affairs at Airbus.

Airbus aircraft are already certified to fly with up to 50% SAF, and through this venture they hope to achieve certification for up to 100% SAF before the end of the decade.

Following the study on SAF into the “Emission and Climate Impact of Alternative Fuels” with the German research centre DLR, this is the second joint venture between Airbus and Neste.

Battery research with Renault for electrification

Airbus and Renault Group have partnered on research and development projects with the goal of accelerating both businesses’ electrification roadmaps and expanding their respective product lines. This agreement, announced during the Airbus Summit, is intended to assist Airbus in developing technology related to future hybrid-electric aircraft.

As part of this collaboration, the engineering teams from Airbus and Renault Group will work together to advance energy storage technologies, components systems that continue to be a major barrier to the development of long-range electric vehicles. The cooperation agreement will specifically cover technology bricks for improving battery weight and energy management, and it will look for the best ways to transition from current cell chemistries (advanced lithium-ion) to all solid-state designs that could double battery energy density by 2030.

In order to prepare for the industrialisation of these future battery designs while evaluating their carbon footprint throughout their entire existence, the combined endeavour will also research the complete lifecycle of future batteries, from manufacture through recyclability.

If it is successful, the collaboration between Airbus and Renault Group on electrification will have significant influence on the transportation environment and achievement of the aviation and automotive industries’ goal of having net-zero emissions by 2050.

CERN bring expertise to bear to assist Airbus with superconductivity

A project to assess how superconductivity may aid in the decarbonisation of future aircraft systems has been launched by Airbus UpNext and CERN, the European Laboratory for Particle Physics. The Super-Conductor for Aviation with Low Emissions (SCALE) initiative aims to encourage the application of superconducting technology in aerial electrical distribution systems.

CERN’s director of finance and human resources, Raphael Bello, stated that the organisation’s research “pushes the boundaries of science and engineering” and collaborates with business to foster innovation with a favourable effect on the environment.

"This partnership with Airbus tests the potential of these technologies to meet the requirements of upcoming clean transportation and mobility solutions."

“This partnership is only a first step in our journey with the European leader in aviation and shows how much we value the excellence of our Member States’ industry,” continued Bello.

To investigate the viability of this technology for electric and hybrid aircraft, researchers are already working on a superconductivity demonstrator called ASCEND (Advanced superconducting and Cryogenic Experimental PowertraiN Demonstrator). The demonstrator comprises of a DC link (cable and cryostat) with two current leads, and Helium gas used to cool the system.

The first results are expected at the end of 2023. CERN will design, build, and test SCALE to Airbus UpNext requirements, and by the end of 2025 the programme hopes to have developed and tested an optimised generic superconductor cryogenic (500kW) powertrain.

Main image: Airbus and ArianeGroup will work together to build the first liquid hydrogen refuelling facility for ZEROe aircraft at Toulouse, Blagnac airport. The station will be operational in 2025. All images credit: Airbus