About KNOTT Slovakia

As a strategic member of the KNOTT Group we develop and produce key products in trailer technology. We are also involved in the production of sophisticated industrial brakes and have evolved into a high-quality airport ground support equipment manufacturer as well. The ability to tailor our products to customer’s needs, along with professional consulting and cooperation since the early development stages of a new product are the main advantages of our company. In addition, the in-house testing laboratory further underlines the reliability of our product design. Paying attention to customer feedback, combining newest technologies with know-how based on decades-long experiences, and the implied highest product quality are characteristic for all companies within the KNOTT Group.

Scroll down

Swipe

Baggage dollies

KNOTT baggage dollies represent a highly durable and reliable solution for passenger’s baggage transport in ramp operations.

They were designed to easily withstand daily rough handling in the harsh airport environment. The chassis is fully welded from high-grade steel while the walls are mounted to be easily replaceable and foldable for more efficient transportation. Core components from renowned manufacturers assure quality and a highly resistant 3-layer powder coated surface treatment pushes the durability even further and contributes to lower service costs.

The rigidity of the frame allows hitching up to 7 trailers together for more efficient operation. Our unique system of automatic sidewall latching is a great help for swift handling as well.

Moreover, the flexibility of our production enables you to get a trailer tailored exactly to your wishes.

- swift handling with automatic sidewall latching

- snap-on basket – mountable tool-free at front or rear end

- tarpaulin or solid steel cover available

- compact freight packaging (stackable by folding all 4 walls)

- specifically designed for the moving of dangerous or valuable goods

- lockable, fully-enclosed cargo space with weatherproof design

- integrated cargo tie-down points

- loading platform equipped with anti-slip mat

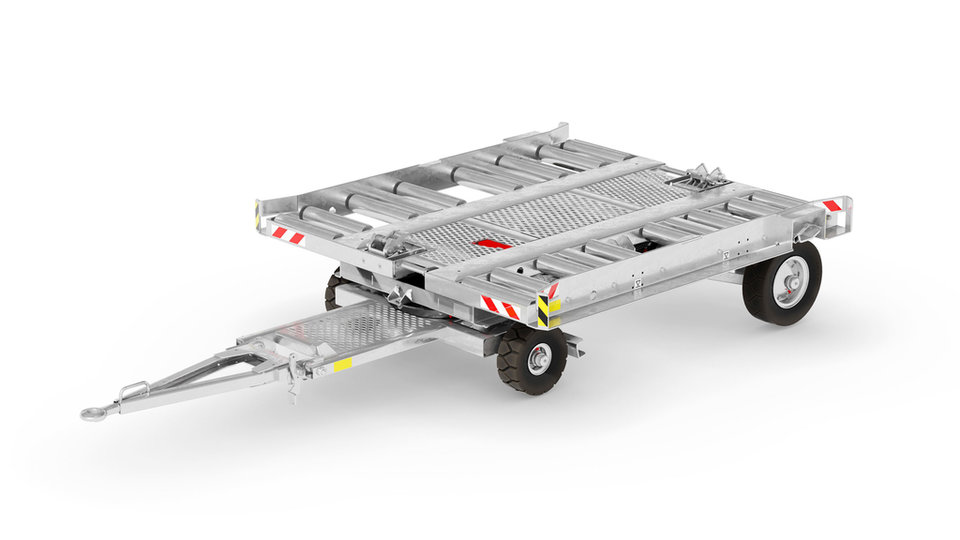

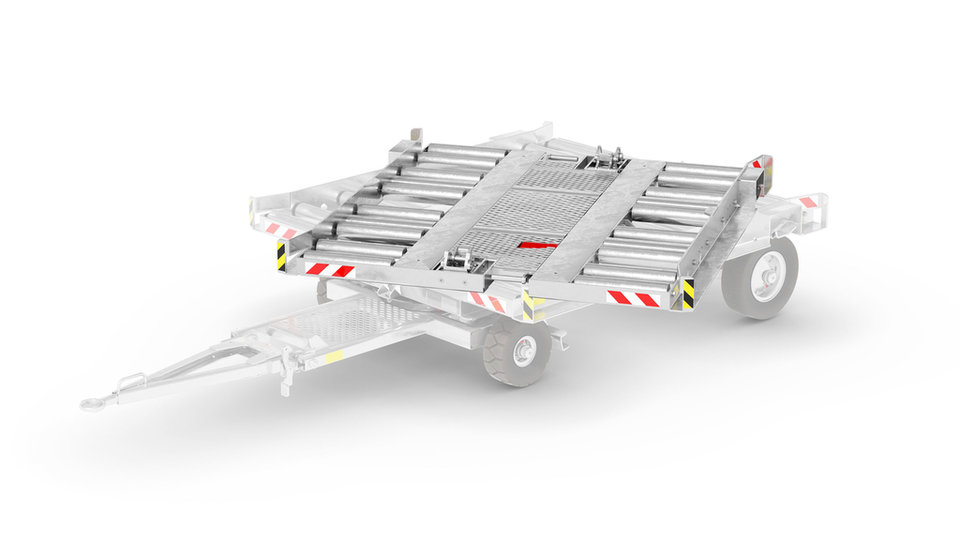

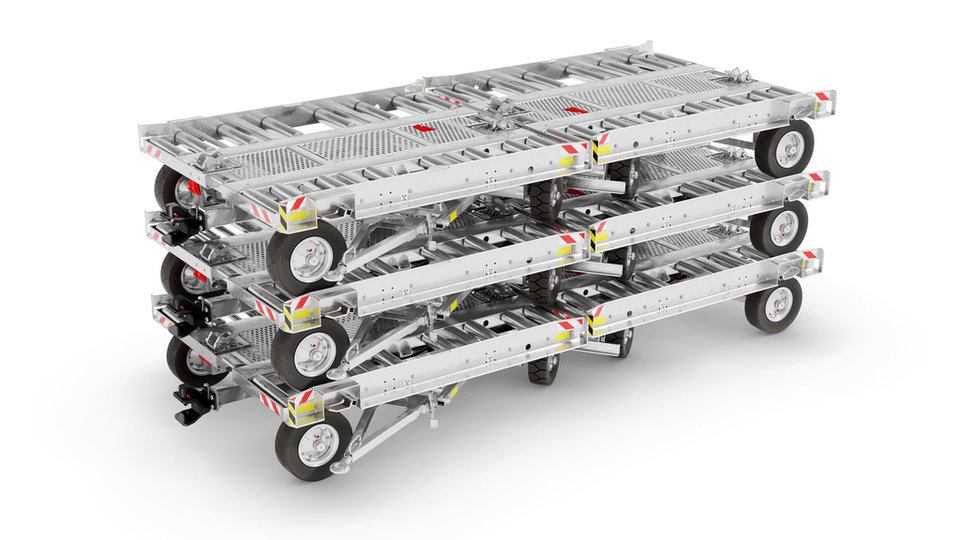

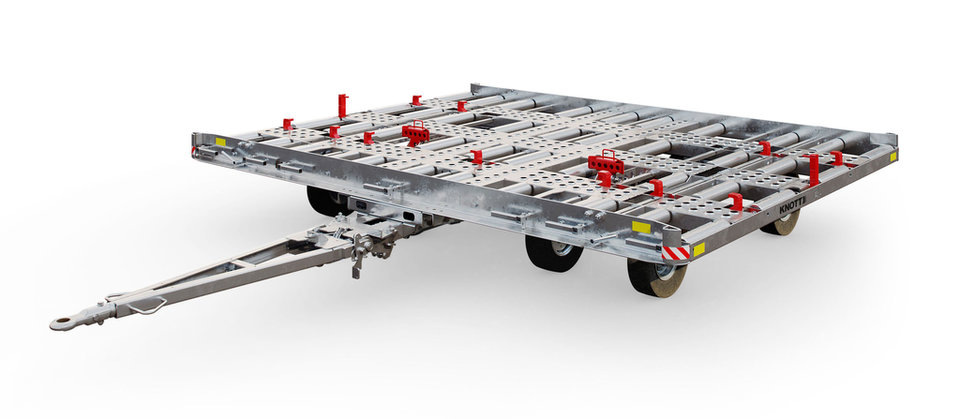

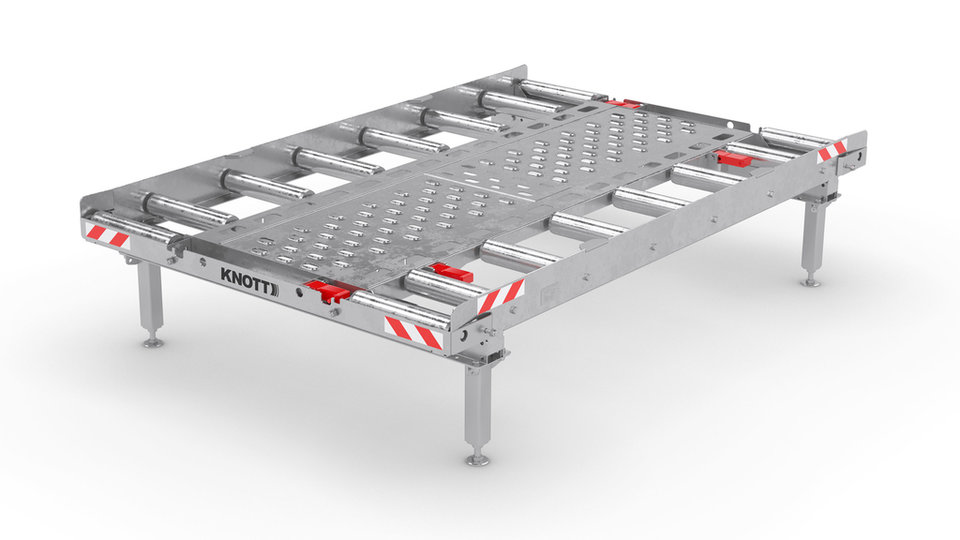

Container / pallet dollies & racks

Container / pallet dollies from KNOTT provide a robust and confident concept for transportation of ULD containers across airport grounds. Characterized by straightforward and simple operation, they guarantee a high efficiency of service.

They were designed as a fully welded construction, made of high-grade steel to cope with rigorous airport operations and thus, often merciless manipulation. High-quality key components from market-leading producers, together with standard hot-dip galvanizing ensure longer operating life and minimal maintenance requirements.

Equipped with durable galvanized rollers, a safe walkover surface in between, and the lead-in side guide rails, they offer a reliable, convenient and secure transportation of containers.

There are also ULD storage racks of various sizes available from KNOTT.

And thanks to the extensive customization options, all of your specific requirements can be met.

- sophisticated foot-operated ULD latching system

- 360° platform rotation with stops at 90° positions

- hitching of up to 7 dollies together

- compatible with all common ULDs / pallets

- centrally operated flip-up ULD stops

- unique concept of trailing front wheels & fixed towbar with swivel function for more convenient hitching

- hitching of up to 4 dollies together

- compact freight packaging (foldable side segments)

- modular storage system

- height-adjustable legs

- weight & cost optimized versions for empty or laden ULDs

- compact freight packaging (stackable by folding legs)

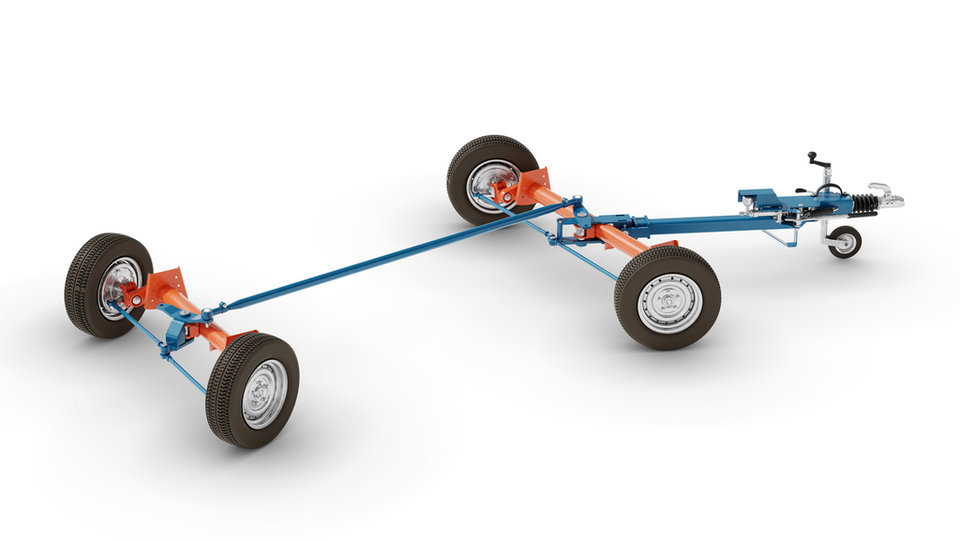

GSE running gears

With trailer chassis components being the main specialization of KNOTT, a truly professional solution with qualified consultancy can be expected. We are experienced in designing a suitable running gear for every application – whether it is a GPU unit, or a trailer for in-plant transportation, construction or agricultural industry, sightseeing train wagons and many more. The possibilities are practically endless with the only limiting factor being the overall loading capacity of 10 tons per chassis. And besides developing a specifically tailored running gear design, we are also able to produce it together with a customer designed lower chassis frame if required.

- braked or unbraked versions possible

- with suspension or as rigid axles

- precise turntable or Ackermann steering available for one or both axles

- parking brake activation by handle, by raising the drawbar or by its lowering to the ground

- hot-dip galvanized or powder coated surface treatment, or even both of them - for superior protection against the most aggressive environments