High quality, know-how and customization

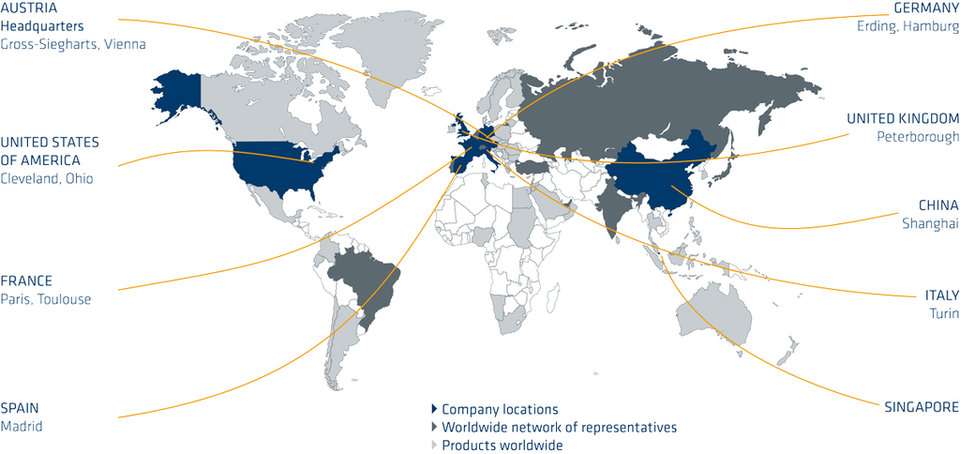

TEST-FUCHS has been the world’s premier aerospace test engineering firm for more than 70 years. Among our many product lines are aircraft generator, hydraulic, pneumatic, and fuel test systems for both military and commercial aerospace applications. Individual customer value at TEST-FUCHS is created by extensive in-house expertise and vertically integrated production capabilities. Additional key activities of this innovative family owned company are the production and maintenance of aerospace components and the production of space components. TEST-FUCHS operates in 12 branches worldwide with over 600 employees.

Water Separation System 4 (WSS4) - Proven quality and powerful results

Aircraft hydraulic fluid monitoring is normally conducted during C-checks, at an interval of one year or less. The hygroscopic nature of hydraulic fluids can result in high water concentration within the fluid, which potentially results in hidden corrosion damage to aircraft control systems. This can often be difficult to localize and is expensive to repair. To combat water absorption, TEST-FUCHS has developed a small vehicle known as the WSS4. Aircraft maintenance teams simply connect the Water Separator WSS4 to the return line between the aircraft and a hydraulic ground power unit (e.g. HGPU50-30-1S). Water is extracted as the fluid circulates during concurrent maintenance activities.

This procedure can potentially prolong the life of the hydraulic medium, thus saving high costs for fluid exchange and also avoids the need for unnecessary hazardous waste fluid disposal. Additional cost savings can also potentially be made by avoiding the replacement of corrosion-damaged components and fluid lines.

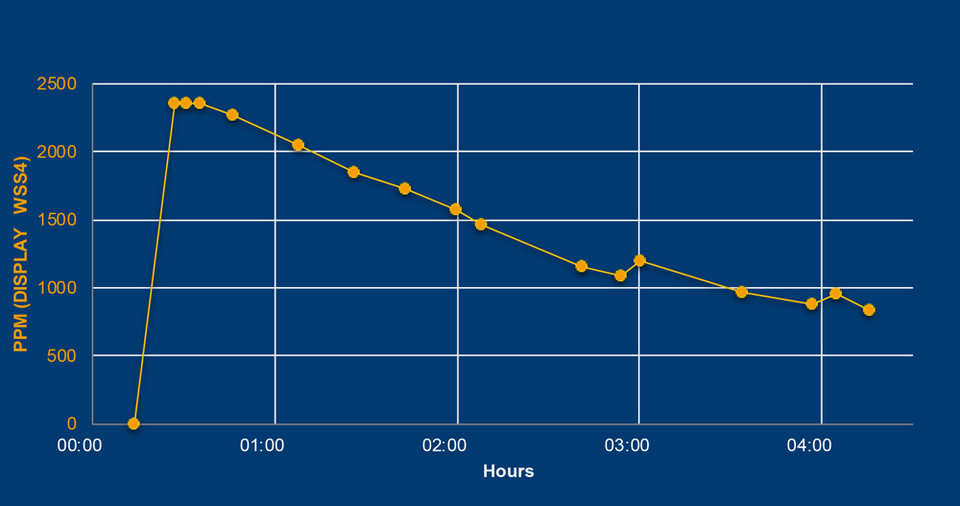

We asked some Airlines to test the Water Separator WSS4, and it was concluded that the quality of the hydraulic medium improved significantly after a purification cycle of only four hours.

Below is a graph which illustrates the results of the field tests, illustrating water ppm versus time (hours). After a short starting phase of 20 minutes, the oil circuit was closed and the cleaning process began. Each dot represents a documented ppm value on the display. The peaks around hour 3 and 4 show movement of flight controls to get all oil out of reservoirs. The water content was reduced from 2,351ppm to 831ppm after four hours.

The Water Separator WSS4 is AIRBUS certified and Boeing NTO can be requested. For more details search the TEST-FUCHS website at www.test-fuchs.com or call any of our regional sales team representatives.

Contact details

TEST-FUCHS GmbH

SALES WORLDWIDE

sales@test-fuchs.com

+43 2847 9001 0